Ajeet Singh

The Dŵr Uisce team is made up of experts from five different disciplines and their research efforts, independently and collaboratively, focused on improving the energy efficiency of the water sector to achieve a more sustainable future. I had the opportunity to work on the heat recovery aspect of the project (under Work Package 2- Drain Water Heat Recovery) which included a mix of computer modelling using Computational Fluid Dynamics (CFD) as well as lab experiments. I love to work with numerical techniques / CFD, having carried out my entire doctorate research in this field.

In details, the two main projects I got involved with were: the laboratory experiments to assess wastewater heat recovery from grease traps; and the monitoring of the pilot heat recovery installation at Penrhyn Castle in Bangor, Wales.

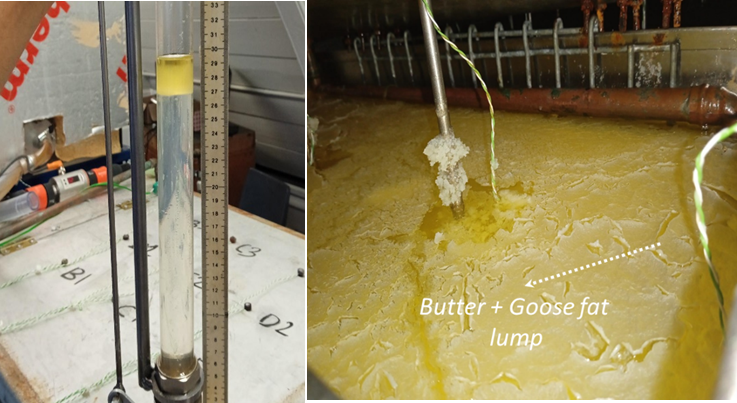

Grease Traps (GT) are devices installed at the wastewater outlet of commercial kitchens to literally trap oils, fat and grease and prevent them to flow down the drain, build up and cause blockages. The focus of my research was on numerical modelling and experiments to predict the heat recovery capability of the heat exchanger integrated to the GT device called hybrid GT device. I found it very interesting to check heat recovery by progressive addition of fat, oil, and grease (FOG) to the hot wastewater. I remember, measurements of FOG level from the GT wastewater was the biggest challenge: starting from the wastewater testing with various chemicals to churning the mix solution with a stirrer for couple of days in the laboratory. Eventually, using a dip stick proven to be the most useful technique for FOG measurement (Figure 1). Optimum design of the heat exchanging unit for the hybrid GT was successfully developed which showed excellent heat recovery potential.

Figure 1: Dip Stick (left); Grease trap Laboratory experiments (right)

Penrhyn Castle: I got the opportunity to monitor heat recycling of a pilot heat recovery setup installed at Penrhyn Castle in 2019 in collaboration with the National Trust (Figure 2). The Castle is a famous tourist destination in Bangor. The café serves food and beverages to the many tourists who visit the castle. The heat recovered from the café hot wastewater is used for preheating the incoming freshwater which reduce the primary water heating demand, and hence the amount of conventional fuel and associated costs. The heat recovery also delivers a reduction in greenhouse gas emissions. The existing temporal mismatch between availability of hot wastewater and heat recovery would require the integration of thermal storage solutions, an interesting opportunity future further research in this field.

Figure 2: Pilot heat recovery installation at Penrhyn Castle

Overall, it has been a great experience working with such a diverse team who actively collaborate to achieve the project aims and objectives and support each other to overcome any challenges. It was a memorable journey as part of the Dŵr Uisce team over the last two and a half years. Last, I would like to thank the team leaders for this great opportunity

A few memories, which I captured in the picutres below!

Figure 3 (left to right): Team meeting in TCD in March 2022; site visits of demo sites in Wales (2022); ferry trip to Bangor.