Madhu Murali

In the past few months, our work related to heat recovery, particularly for industries, has been focused on experiments using our lab-scale Dissolved Air Flotation (DAF) tank at Trinity College Dublin. The background to this work is detailed in our previous blog post. Recently, our researchers have been trying to characterize the flow of water and dissolved air within the DAF tank. This characterization will be used to calibrate and validate the performance of a computer model of the DAF tank as well as look at the impacts of placing a heat exchanger in different parts of the lab-scale DAF tank. To assist with the flow characterization, a plexiglass viewing window was installed on our lab-scale DAF tank (Figure 1) by the technical staff at the School of Engineering in Trinity College Dublin.

Figure 1: Lab-scale DAF Tank

Our researchers have been using the viewing window to get a look into the internal flow dynamics of the DAF tank and use a camera to record the development of this flow.

A somewhat unorthodox recording setup (Figure 2) was required to make these videos to reduce glare and capture enough detail.

Figure 2: video recording set up

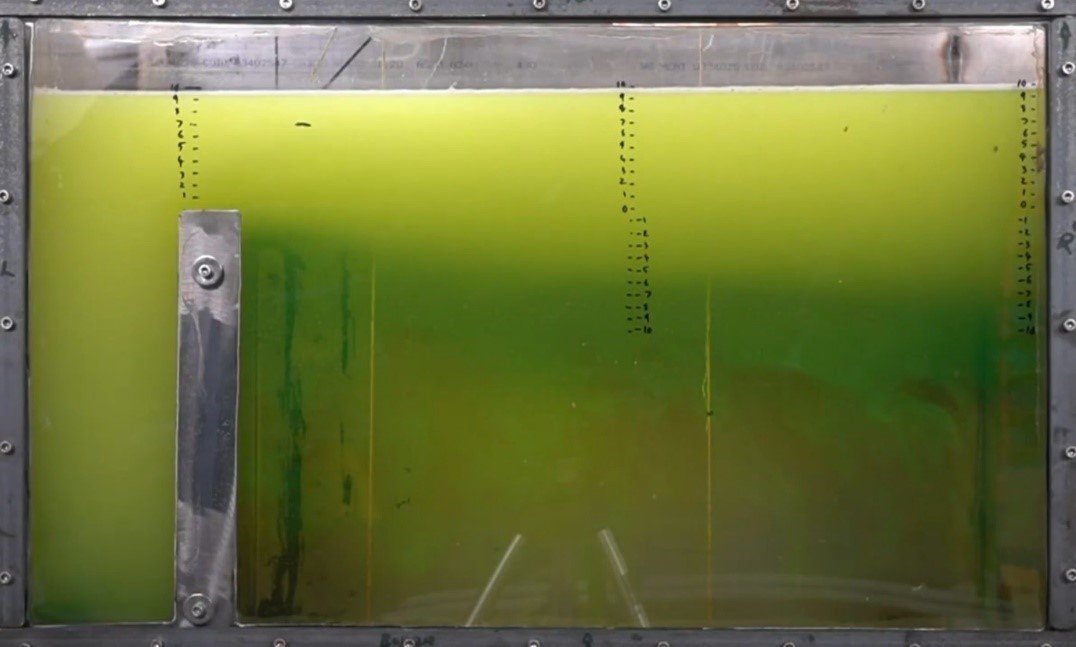

Some initial video outputs showing the development of the plume of microbubbles in the tank (Figure 3) and the tank after the introduction of fluorescein dye (Figure 4) are seen below.

Figure 3: development of the plum in the DAF tank

Figure 4: Additional fluorescein dye added to help visualise the plum

You can watch the video below.