DWHR at the Tea Rooms kitchen drain in Penrhyn Castle, Wales

Figure 1: Penrhyn Castle

This National Trust demonstration site at Penrhyn Castle in Wales has been operational since Autumn 2019. The construction and commissioning phase finished in February 2020

Temperature monitoring of the drain water from the kitchen at Penrhyn castle has shown promising temperatures of up to 60°C, and a thermal gradient of greater than 30 °C has been attained which widens the scope of heat recycling from the wastewater flushing down the drain. Using vertical heat exchangers this demonstration site aims at showing direct heat recovery methods from kitchen drain water and is testing different configurations of the drain water heat recovery (DWHR) system.

Proposed system

The first configuration is the simplest one, simply preheating the incoming water. This low-cost and uncomplicated solution has the disadvantage of being very vulnerable to mismatches between drain water heat availability and kitchen hot water demand (Figure 2).

The second configuration attempts to counteract those mismatches by recirculating the preheated water, from a holding tank, through the heat exchanger in the drain. This has the advantage of ensuring that every time water flows through the drain, part of the heat will be recovered. The disadvantage is the increased complexity of the system, and additional consumption in the circulation pumps.

Figure 3: Third configuration of the DWHR system, preheating and recirculating mains water

Figure 2: First configuration of the DWHR system, preheating the mains water

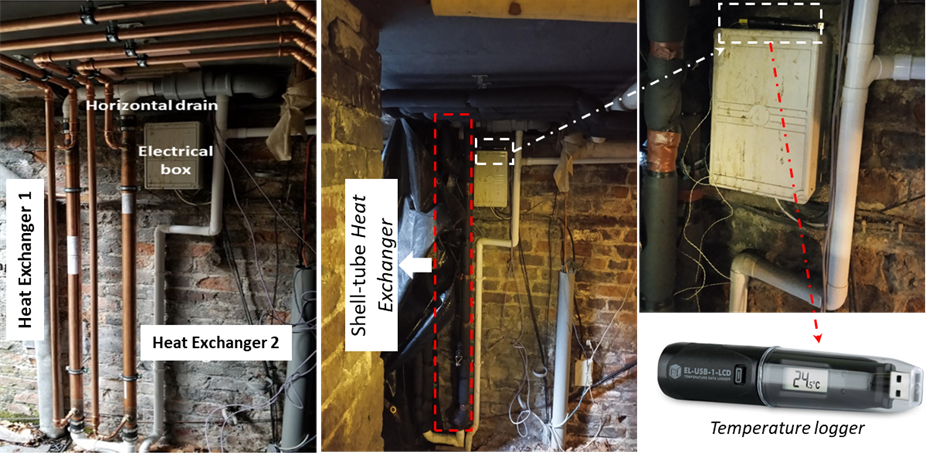

The third configuration (Figure 3), combining both systems, is expected to recover the largest amount of heat. However, it’s the most complex solution. The demonstrator will be used to make a trade-off between this increased complexity and the benefit of increased heat recovery, and to observe the operation of such systems in a real-world application (Figure 4).

Figure 4: DWHR system components

Objectives of the demonstrator

The system, regardless of its configuration is expected to save about 25-40 % of the primary water heating consumption of the kitchen. This heat is currently provided by a main heating loop, where the heat is generated in a biomass boiler house and then pumped to the rooms in the castle. The savings are thus expected to be twofold: not only will the pellet consumption of the boiler be reduced, but, more importantly, the electricity consumption of the auxiliary devices, such as the water pumps, will decrease as well. Expected greenhouse gas emission savings are just over 780 Kg CO2e.

Figure 5: Heat recovered from Feb to Jun 2022 in kWh

During the period Feb-June 2022 of the current tourist season at Penrhyn Castle, the DWHR system has saved over 900 kWh of heat from the kitchen drain of the Tea Rooms (Figure 5).

Virtual 3D Tour

Are you interested in taking a closer look at system? Click below to take our 3-D tour (English and Welsh versions available).

https://dwruisce.github.io/PenrhynE/

https://dwruisce.github.io/PenrhynW/

In the press

Pioneering system ensures money doesn't follow water down the drain

Water going down the drain isn’t money down the drain for National Trust Cymru’s Penrhyn Castle

Castle Pioneers waste-water heat capture technology

Wales-Ireland joint project explores energy efficient water solutions

Engineers trial new tech to stop energy going down the drain